I have to agree with David. Your cross-section with the 50um scalebar

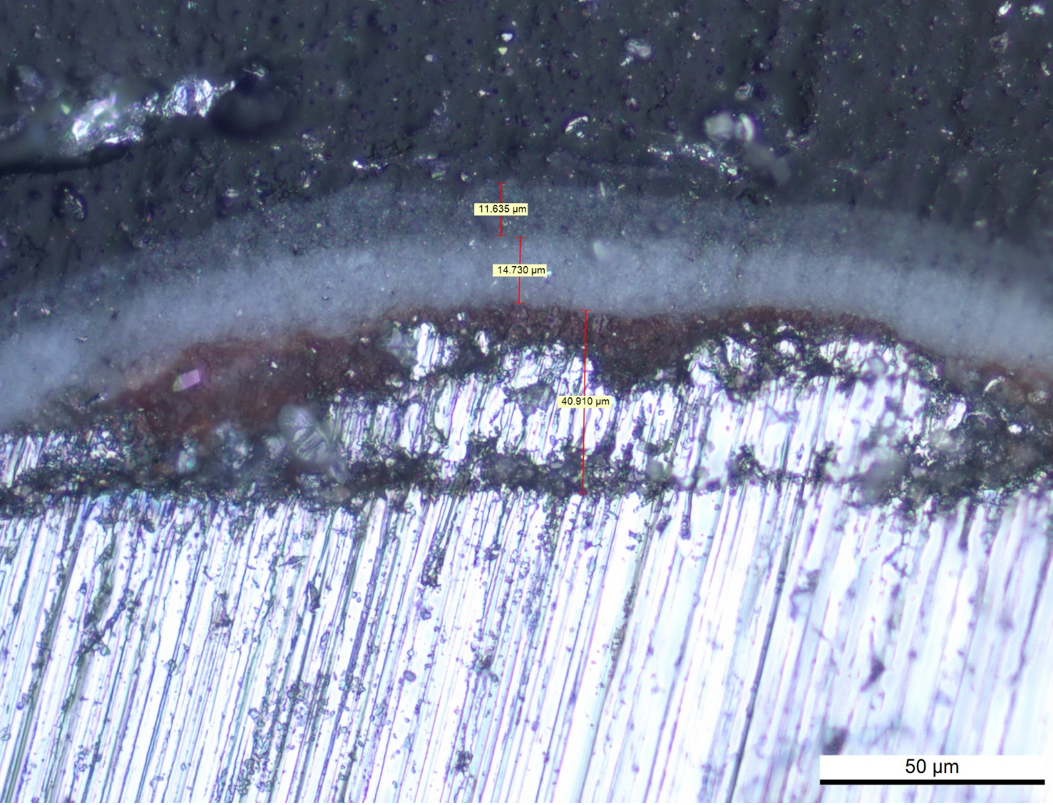

shows unidirectional gouges/scratches greater than 1um wide. You need

the bubbled region.

Original Message:

Sent: 4/29/2024 3:27:00 PM

From: David Coulston

Subject: RE: Investigation on Progression of Corrosion Under Protective Layers on Car Door

Vikram,

The fact that you have steel in the bubbled area is a bit of a concern. I assume that it ended up there during metallographic preparation. Before closing out the investigation, I would recommend preparing another sample after consulting with an experienced metallographer. Generally one might section a distance away from the region of interest, then mount in epoxy and grind into the ROI using 180, 320, 600, 800 (or 1200) grit SiC papers, then polish with a 3 micron diamond film, to keep things flat. This might give you a better look at what is REALLY under the bubble... and better direct you to a solution.

------------------------------

David Coulston

Niles MI

------------------------------

Original Message:

Sent: 04-29-2024 02:13

From: Vikram Tomar

Subject: Investigation on Progression of Corrosion Under Protective Layers on Car Door

Greetings fellow ASM members,

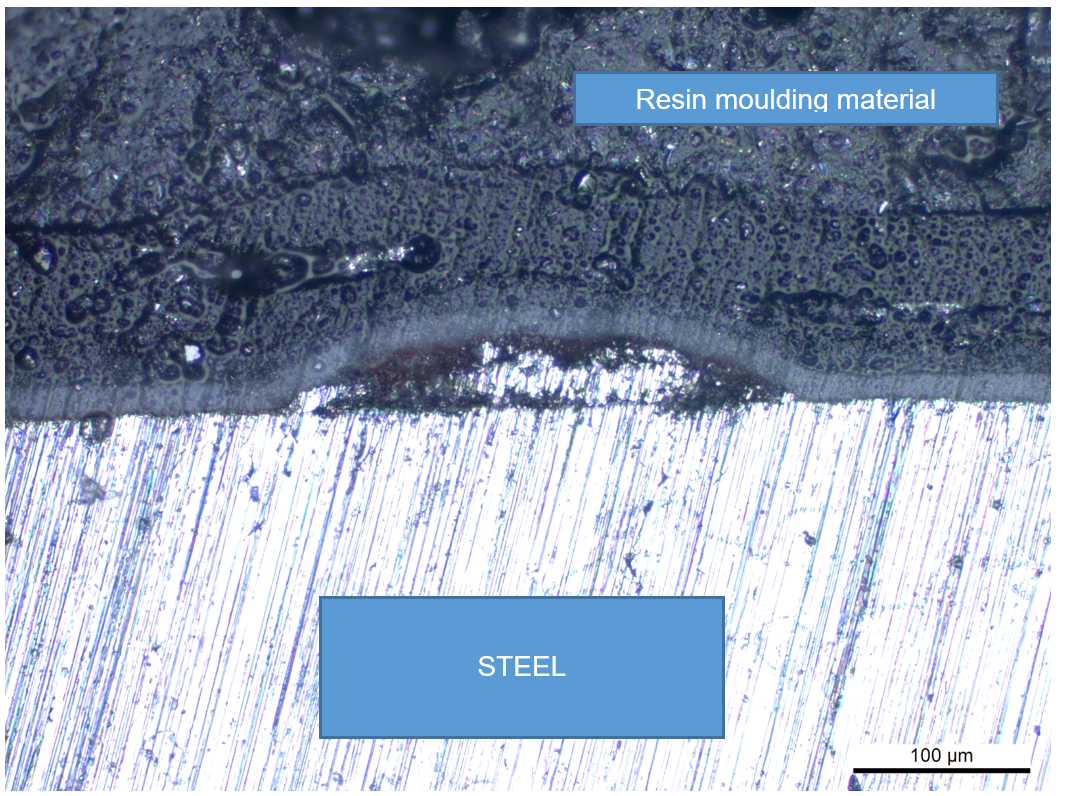

I am investigating a blister-like defect on a car door, specifically near the weather strip mounting area. The paint and coating sequence on the steel is as follows: pretreatment layer, CED layer, primer layer, base coat layer, and clear coat layer.

After extracting a microsection and examining it under a microscope, the micrograph (second image) suggests corrosion initiating from the base material, as evidenced by the third, zoomed-in micrograph of the second image. It appears there may have been rust on the steel that was not adequately treated before the subsequent layering processes were applied.

My concern is that the pretreatment layer next to the corroded area may not be adhering properly, possibly leading to an increase in corrosion products under the CED or pretreatment layer over time. This could cause the layer to lift from the base layer, as shown in the micrograph.

With this context, I have two questions:

- Is it possible for corrosion to proceed between protective layers and the initially microscale corroded steel from the base material itself?

- Could corrosion advance due to moisture seeping through the paint layers to the base material, even with the presence of protective coatings?

Any insights or experiences with similar defects would be immensely valuable

------------------------------

Vikram Tomar

material engineer 2

atotech

Meerut

07017475745

------------------------------