It is 5160H solid bar heat treated in open atmosphere walking beam furnace just above the transformation temperature, the issue is only with one part. The higher mag micros are attached. It does not appear as a slack quench phenomenon, because it is very similar to as received micro.

------------------------------

Sanjay Kulkarni

Materials Engineer

MSSC

2040 Crooks RD, Suite A

Troy, MI 48084

sanjay.kulkarni@msscna.comCell: 248-840-1056

------------------------------

Original Message:

Sent: 10-26-2023 11:32

From: Michael Zielinski

Subject: Pearlite formation on Heat treated Part

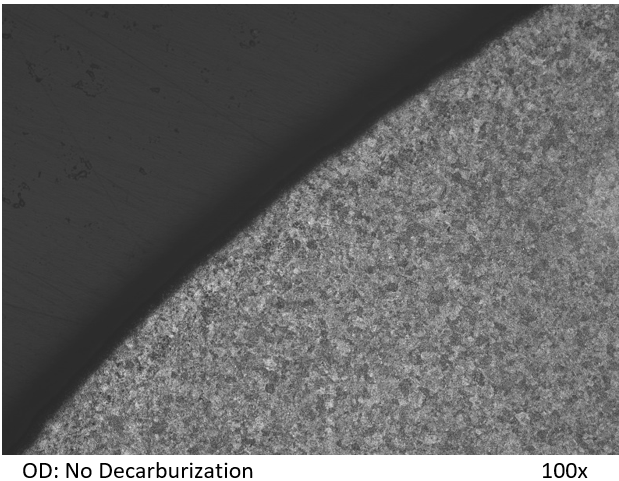

What is the base material? What is the heat treatment? Could be atmosphere in the furnace causing decarb on the surface, leading to a "slack quench" on the surface. Please provide more details of the heat treat process.

Thank you

------------------------------

Michael Zielinski

Lehigh Univ

Easton PA

90846973332218

Original Message:

Sent: 10-25-2023 10:56

From: Sanjay Kulkarni

Subject: Pearlite formation on Heat treated Part

Our plant had a issue of surface anomaly as shown below.

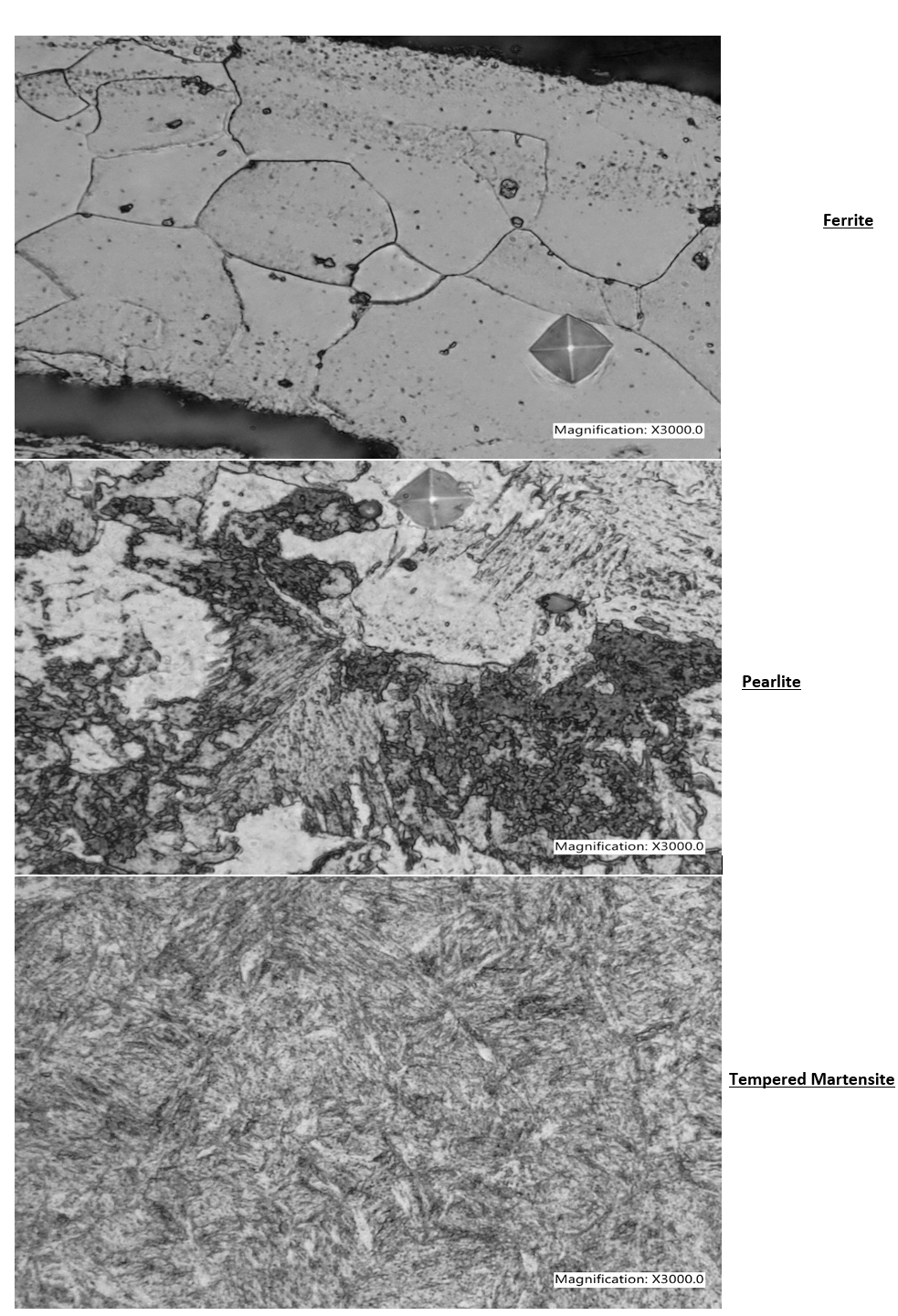

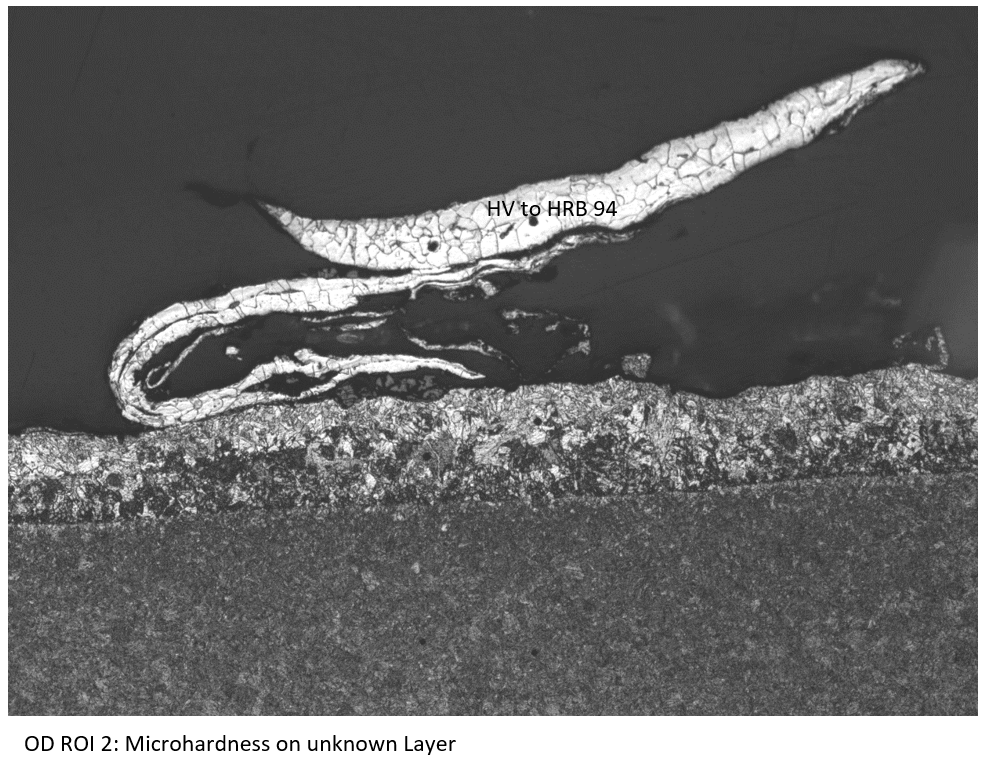

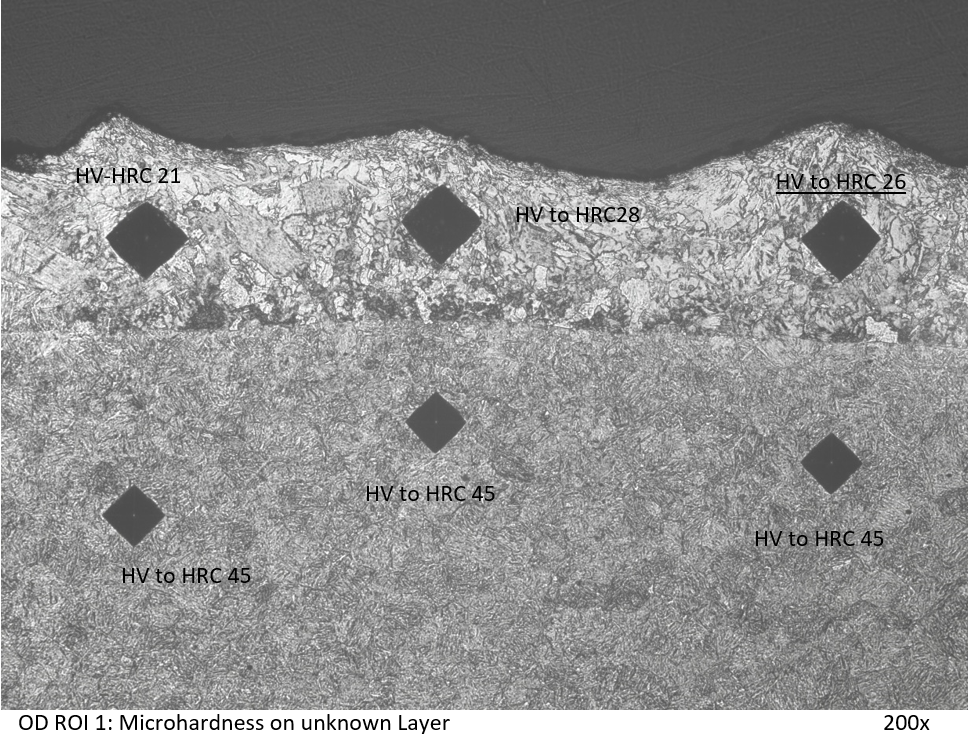

I received the part for analysis. I cut the longitudinal sect of surface anomaly. and found the following phases. Although the root cause was the kerf process which was carried out in steel mill based on the lamination of soft layer (Ferrite) on base material (Fig.1).

My question to me is, if it was from steel mill then how come I see the pearlite formation on heat treated part? rest of the OD is free of decarburization (fig.2). Please explain.

------------------------------

Sanjay Kulkarni

Materials Engineer

MSSC

2040 Crooks RD, Suite A

Troy, MI 48084

sanjay.kulkarni@msscna.com

Cell: 248-840-1056

------------------------------